-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

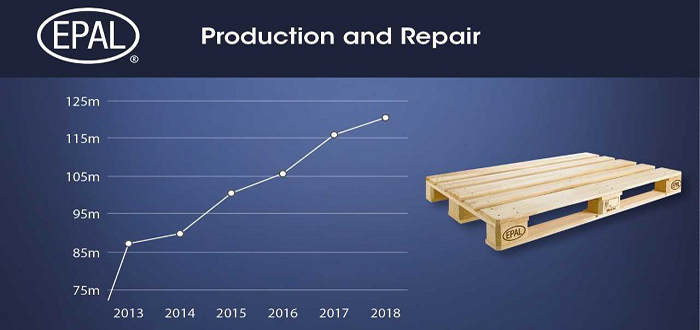

Strong result: 121.8 million EPAL load carriers in 2018

EPAL ended 2018 with over 100 m EPAL load carriers produced and repaired for the third consecutive year

In 2018 EPAL again achieved a positive result with 121.8 m EPAL load carriers produced and repaired. Compared to the previous year, this is an increase of 5.2% (2017 total: 115.8 m units). If you consider production and repairs separately, then in 2018, 93.9 m EPAL load carriers were produced, 6.3% more than in 2017. The repair figures stood at a solid 27.5 m units, like in the previous year. The increase in the production of EPAL Box pallets in 2018 was outstanding: with 408,076 Box pallets produced, this result was 30% more compared to 2017.

Christian Kühnhold, EPAL’s CEO commented, “Thanks to the hard work of all licensees, but also due to the solid strong demand in the FMCG sector, in general industry markets and the automotive supply industry, EPAL also had a correspondingly positive development. On this basis, we, EPAL want to work hard in all relevant areas and provide the tools, so that the open exchange pool develops even further. This concerns the further development of existing load carriers, e.g. intelligent EPAL pallets or the market launch of new load carriers, such as the independently inspected EPAL CP pallets.”

For nearly thirty years EPAL Euro pallets have been the heart of logistics, they move flows of goods globally and are essential for the safety and smooth operation especially in automated high-bay storage. The huge number of A and B quality pallets from high-bay storage ensures that the open Euro pallet pool is the most extensive exchange pool of all. Users of EPAL Euro pallets take advantage of the benefits of the open pool, the EPAL system, whose cornerstone is the continuous availability and global exchangeability, cost transparency and contractual independence.

EPAL’s DNA, the essence of which is independent quality assurance as well as legal action against counterfeit pallets, goes hand in hand with the EPAL system.

Environmental responsibility and sustainability are additional key components of our DNA.

Thanks to the reusability of EPAL pallets in the open pool, logistics costs and CO2 emissions can be reduced. EPAL pallets can be repaired with lower materials and energy costs and at the end of their life cycle, are completely recyclable.