-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

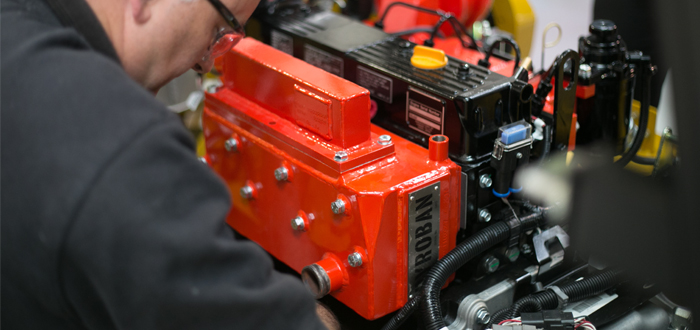

How To Build An ATEX Forklift.

To comply with European legislation, forklifts operating in potentially explosive atmospheres require special conversion to reduce the risk of ignition. But what does this involve? Safety company Pyroban explains.

“A very small percentage of forklifts are used for operations in Zone 1, 2, 21 or 22 hazardous areas,” explains Steve Noakes, Group Engineering and Operations Director for Pyroban. “Therefore, equipment manufacturers (OEMs) are not usually able to invest in making trucks that come off the production line compliant with explosion protection standards. Instead, OEMs work with specialists like Pyroban.”

The Regulations:

Explosion protection conversion company Pyroban modifies forklift trucks to conform with ATEX 2014/34/EU* requirements, and standards such as EN1755:2015*, which covers all equipment and protective systems intended for use in potentially explosive atmospheres. For example, a chemical factory or waste management site that needs to comply with ATEX 1999/92/EC and keep their people safe.

Assessment:

When Pyroban receives the truck for conversion, it conducts a full assessment to identify and evaluate ignition risks.

Using the requirements of EN1755:2015 as a guide, Pyroban’s specially trained engineers assess all mechanical and electrical components to determine if they could cause ignition, by generating heat or a spark. This can include switches, sensors, relays, contactors, motors, generators and controllers, as well as brakes, transmission, hydraulics, forks, the engine and the exhaust. The interior and exterior are also evaluated extensively, including parts such as seats, armrests, panels, the cabin and tyres.

“The engineers assess each component for risk during normal operation with the intended Zone for operation in mind,” says Steve. “For example, the ignition of either gas or vapour for Zone 1 and 2 areas, or combustible dust for Zone 21 and 22 operations.”

Conversion:

Once evaluation is complete, the conversion can then be started. This varies in complexity depending on both the make-up of the truck and the specific needs, and hazards, of the end user’s application. Sometimes original components will be replaced with an ATEX compliant explosion protected version. Other parts will be modified, for example the electrical interface between the part and the control system may be adapted. This is done in close collaboration with the OEM to ensure the part and the truck still perform exactly as intended.

Testing and Certification:

Having applied the explosion protection conversions, Pyroban conducts tests to verify that the systems are functioning correctly, and in line with ATEX requirements. After the required modifications have been validated, the vehicle is then returned to the OEM where the CE mark can be applied, certifying the truck for use in the required hazardous zone in line with European legislation.

“The whole explosion protection conversion process may seem labour intensive, as it can take from 4 to 12 weeks, with up to 600 hours work by Pyroban’s experts,” says Steve. “However, as it only takes one small spark to cause a disastrous explosion, it’s important for businesses to understand why there are no shortcuts when it comes to explosion protection.”

For more information, visit www.pyroban.com, call +44(0)1273 466200 or email [email protected].