-

Tower Launches Customer Sustainability Hub with Practical Tools for Lower-Impact Pharmaceutical Cold Chain - October 16, 2024

-

Six decision-making models for best practice WMS digital transformation - October 16, 2024

-

“Transforming Logistics: Precision and Purpose” – BIFA takes centre stage - October 15, 2024

-

JAMES JONES & SONS LTD EXPANDS ITS PALLETS & PACKAGING DIVISION THROUGH THE ACQUISITION OF HG TIMBER LTD - October 10, 2024

-

HUGO BECK EXPANDS MACHINE RANGE FOR E-COMMERCE, MAIL ORDER AND LOGISTICS - October 10, 2024

-

Winning Irish Exporter of the Year, Combilifts CEO Martin McVicar talks about the journey into the Global Market - October 8, 2024

-

JAMES JONES & SONS’ AUSTRALIAN SUBSIDIARY, HYNE GROUP, EXPANDS TO WESTERN AUSTRALIA - October 3, 2024

-

QUECLINK LAUNCHES SOLAR-POWERED ASSET TRACKER FOR TRAILERS AND CONTAINERS - October 3, 2024

-

Southgate Global Calls for Greater Health and Safety in the Warehouse Back Care Awareness Week - October 3, 2024

-

Nulogy to Expand Capabilities with Strategic Acquisition of Mingo Smart Factory - October 3, 2024

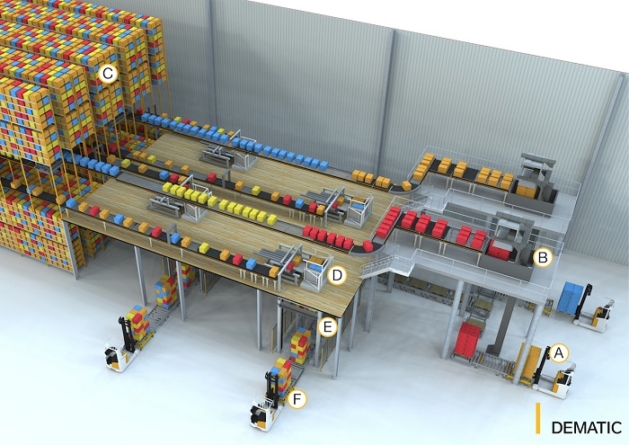

Store-friendly-sequencing through warehouse-friendly automation.

Store-friendly-sequencing holds the potential to boost sales and reduce in-store costs on the high street. But how do you step-up the pace in the warehouse without having to rebuild it? By Matt Weston, Head of Solutions Design, Dematic Northern Europe and Noë van Bergen, Business Development Mobile Automation EMEA, Dematic Egemin.

As online competition escalates, retailers are under growing pressure to maximise the value and performance of their high-street estates. To do so, many are adopting the practice of store-friendly-sequencing to free-up stockrooms for the more profitable purpose of displaying an increased range of goods – boosting sales and increasing profitability.

An additional benefit of the technique is the time saved by staff when replenishing shelves and racks, as mixed goods arrive pre-stacked in shelf sequence according to store plans, allowing greater attention to be given to helping customers.

Originally developed by the grocery sector, the practice is now becoming more widely adopted by department stores and fashion chains – making in-store operational efficiency the new battleground for retailers. Who needs a stockroom when pallets and roll-cages arrive stacked with goods stripped of outer packaging and all sequenced in shelf order?

However, there are a number of critical issues to address. Achieving in-store efficiency requires careful preparation of loads in the distribution centre – and that takes a well-ordered sequence of operations.

Within the warehouse, traditional labour intensive methods of preparing mixed case pallets for store replenishment are coming under increasing strain, as up-scaling of operations and tightening labour resources take their toll on productivity. Huge, low-height warehouses bustling with manual activity are no longer seen as the way forward by leading brands. Instead, a newly developed strategy integrating robotics, driverless forklift trucks, automation and artificial intelligence is fast becoming the preferred solution – giving scale, accuracy and consistency.

Critically, this union of technology allows the advantages of automation to be realised within retailers’ existing 10 – 15 m high warehouses and existing pallet racking. Until recently, a constraint on the adoption of automation for case-pick and pallet assembly has been the notion that the height of existing warehouses needs to change in order to house large automated high-bays.

This thinking is changing, thanks to more flexible solutions that combine Dematic’s Automated Mixed Case Palletising (AMCAP®) with Dematic Egemin’s advanced technology for driverless forklift trucks. Existing warehouses can now be transformed internally and upgraded in a flexible and scalable way, radically shrinking the floor space needed to prepare store-friendly-sequenced unit loads. This combination of bringing AMCAP® and Automated Guided Vehicle (AGV) technology together creates a seamless solution.

Dematic’s AMCAP® is a high-performance palletising system designed to assemble pallets that are ready for easy shelf re-stocking at the retail store and is flexible enough to cater for differing store layouts. As it combines scalability with a compact footprint, it can be easily integrated into existing facilities. The design allows flexible throughput variations up to several thousand cases per hour, bringing the cost per case down from typically 12p, for manual operations, to 5p with AMCAP®.

In effect, AMCAP® is an automated robotic system comprising three distinct processes: Case De-palletising, where cases are taken from the stock pallet using a robot or hoist equipped with vacuum and side clamp technology: Case Storage and Retrieval using a Dematic Multishuttle® store (DMS), where de-palletised cases are temporarily stored; and Pallet Building where products from the DMS are re-oriented and assembled onto a pallet or roll-cage, either semi-automatically or fully-automatically, as required, and then wrapped in-situ before being labelled and taken away by conveyor or Dematic Egemin driverless vehicle to dispatch or storage.

Dematic’s AMCAP® system has evolved significantly over the last five years. Early projects required cases to be placed on trays with bespoke plastic bases, but continued development has now completely eliminated the need for a tray on in-bound cases, which in turn has removed the requirement for dedicated equipment for ‘traying’, ‘de-traying’ and tray buffering. Direct case handling from de-palletiser to palletiser lowers the risk of accidental damage to cases and saves costs, as well as space. In addition, product is securely tracked from pallet to case, which cuts out the need for reading case barcodes.

The intelligence behind the whole AMCAP® process is Dematic’s iQ Pack Builder software, which directs pallet building according to how the retailer wants to receive the cases – by family group or store planogram. Cases arrive at the palletiser in precise sequence and are automatically loaded accordingly. When the mixed-case pallet arrives in store, the cases are unloaded in order of the plan, minimising shelf-stocking time.

However, it is the marriage of AMCAP® technology with Dematic Egemin’s expertise in creating driverless vehicles from KION Group manufactured forklift trucks that brings some of the greatest rewards. By automating standard very-narrow-aisle trucks and low-level pallet trucks existing, conventional racking installations can be fully utilised and easily upgraded to efficiently move in-bound pallets of product in and out of storage, feeding the AMCAP® cells as demanded by Dematic’s iQ control software. In turn, completed mixed case pallets or roll-cages can be taken away by driverless trucks to either despatch bays or storage.

Importantly, Dematic Egemin’s HYBRID automation pack, comprising intelligent software, sensor, safety systems controls and navigation technology, makes fully automated guided vehicles from standard warehouse trucks, enabling them to be driverless, navigate and handle goods automatically, whilst still retaining the ability to be manually driven.

Using Dematic Egemin’s traffic management software, 360° intralogistics automation can be readily achieved, optimising the control and allocation of vehicles across the entire system from goods received, Very Narrow Aisle (VNA) pick and drop stations, and storage and retrieval, to taxi movements for AMCAP® cells and take-away to dispatch.

A further significant advantage of scaling up to automation using Dematic Egemin controlled vehicles is that the trucks can be manually operated if required and automation can be introduced in stages – as demand dictates – giving scalability, without the need to undertake expensive structural changes to the building. Facilities can remain accessible and user friendly, free from the physical barriers imposed by fully automated high-bay and conveyor systems.

If retail organisations are able to automate their existing distribution centres using AMCAP® technology coupled with Dematic Egemin driverless trucks, then achieving productivity and instore cost improvements on the high street – with all the potential to grow sales and boost profits – becomes a realistic and irresistible option.