-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

The Two Levers of Inventory Optimization.

By Henry Canitz, Director of Product Marketing & Business Development, Logility

I have a mechanical engineering degree so when I hear the term “Lever” I tend to think of the Physics and Mechanical Design courses I took some 30+ years ago. However, from an inventory optimization viewpoint, “Working Capital” and “Customer Service Levels” are the available levers.

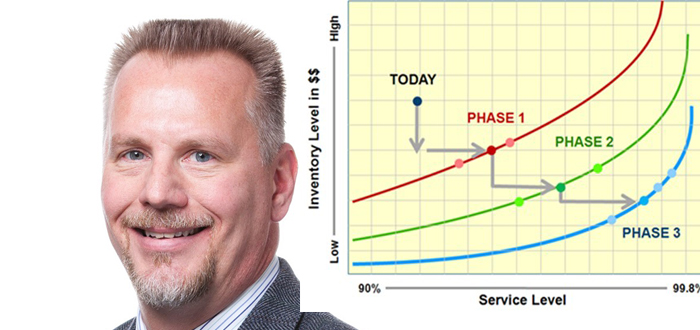

Your company’s inventory efficient frontier is a tradeoff curve between working capital and service level and represents the current achievable service level at any corresponding inventory investment. Chances are you are not on the inventory efficiency curve because in practice there are always inefficiencies. However, if you could eliminate all inefficiencies, failures, etc. and estimate how much your service level will go up and down with changes in inventory investment you would end up with a curve – your current inventory efficient frontier curve. Organizations can slide up and down along this curve by manipulating the service and working capital levers.

However, only by shifting the inventory efficient frontier can you create real value. Inventory optimization solutions let you do exactly that, location by location. However, as you probably know, the only way to optimize inventory across the entire supply chain is through Multi-Echelon Inventory Optimization (MEIO), which allows you to shift to a new efficient frontier for your entire supply chain.

By modeling the end-to-end supply chain, MEIO determines not only the optimal inventory to carry at each location but also at what locations each item should be carried. MEIO looks across sales channels, distribution tiers, and even types of inventory (raw, WIP, FG) to understand how best to minimize total inventory while still providing the desired customer service levels. MEIO can take you into unexplored territory providing reductions in working capital of up to 30 percent or more. That is an impressive use of levers.

What is important to understand is that the supply chain is a living, breathing and constantly changing beast. Your optimal inventory strategy for this month might be suboptimal next month. Modeling your end-to-end supply chain inventory is not a one and done activity and so there is always opportunity to shift that efficient frontier into new and undiscovered territory.

Do you understand your company’s service level – working capital tradeoff? Can you model your end-to-end supply chain to determine your optimal inventory locations and levels?