-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

Collapse and unfold in no time.

At FRUIT LOGISTICA 2018 in Berlin (February 7-9, 2018), the specialist for plastic load carriers, Cabka-IPS, presents its proven Drybox with a brand new feature: the collapsible storage and picking container is now equipped with the innovative active-lock closure mechanism. This makes it even easier to handle the box, as it can be folded quickly and set up again in no time.

The Cabka-IPS Drybox has been successfully used in automated packing and order picking stations for several years. The users especially appreciate its high process reliability: the collapsible container is extremely robust and stable with a load capacity of 25 kilograms. It can be used failure-free and efficiently on roller conveyors and other conveyor and storage systems. The Drybox features an impressive reaction time when accelerating and decelerating. In addition, when empty it can be reduced from 26 centimeters to only 36 millimeters, despite its large interior height. This saves significant storage and transport costs.

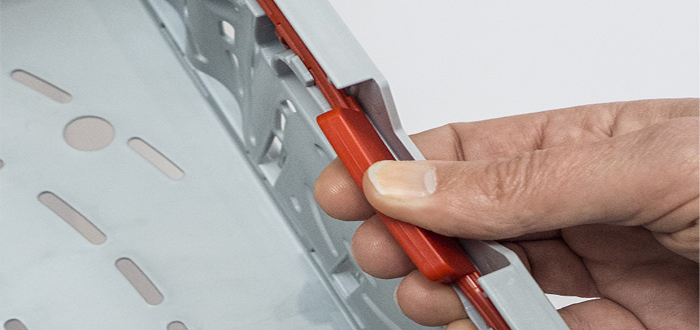

The active-lock closure mechanism gives the Drybox a practical locking system, which is already familiar from the proven Twistlock Box from Cabka-IPS. The container features two rockers on the short sides, which the user can easily push inwards. This unlocks the walls, which can then simply be collapsed. To set up the Drybox, the side parts are simply raised and the locks snap in all by themselves. This significantly facilitates the handling of the boxes and saves valuable time in numerous warehouse and logistics processes.

Cabka-IPS at Fruit Logistica in Berlin: Hall 21 | Booth B-03.