-

ROSSLARE EUROPORT TARGETS HEALTH & SAFETY WITH CAMERA TELEMATICS PARTNERSHIP - 2 days ago

-

Landmark Study Reveals Wearable Robotics Significantly Boost Safety and Efficiency in Industrial Environments - July 24, 2024

-

Visku Tackle The Retail Seasonality Challenge One Pallet At A Time - July 22, 2024

-

KAMMAC AND BERGEN LOGISTICS STRENGTHEN FASHION & LIFESTYLE SERVICES IN THE UK - July 19, 2024

-

TENTBOX EXTENDS PARTNERSHIP WITH ARROWXL TO SUPPORT INCREASING DEMAND - July 17, 2024

-

The Perfume Shop improves customer journeys while driving profitability in partnership with Scurri - July 17, 2024

-

ZEROMISSION SECURES £2.3M ($3M) INVESTMENT TO ACCELERATE ELECTRIC FLEETS - July 16, 2024

-

BCMPA CELEBRATES SUCCESS OF 2024 CONFERENCE - July 15, 2024

-

Best of the Best: Jungheinrich Celebrates Triple International Award Win - July 12, 2024

-

GOPLASTICPALLETS.COM CALLS ON NEW CHANCELLOR RACHEL REEVES TO CONSIDER PLASTIC PACKAGING TAX REFORM - July 10, 2024

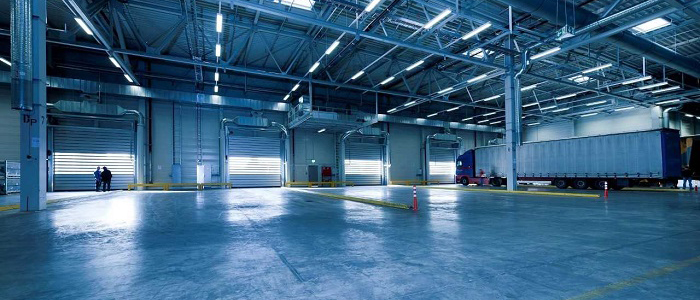

How warehouses can reduce their carbon footprint

It pays for businesses to be carbon conscious. With climate change becoming an increasingly bi-partisan issue, the PR value of operating green and efficient warehouses is substantial, even if the issue doesn’t give you sleepless nights. Moreover though, going green can save a substantial amount of money in the long-term, which you can invest straight back into the business.

While there are two obvious areas for improvement in the carbon footprint of warehouses – namely lighting and heating – it can be difficult to know how to improve these. Thankfully, a relentless focus on improving these traditional problems has yielded a range of novel solutions. Here are just a handful of ways in which warehouses can improve their use and retention of energy, and reduce their carbon footprint in the process.

Smart lighting

Sufficient lighting in a warehouse is a significant safety issue, and many warehouses solve the problem by flooding the entire area. This ‘safety first’ approach is admirable in some respects, but it’s also no longer necessary. New technology means it’s possible to light only the areas which are in use, significantly reducing the energy used on warehouse lighting.

Motion sensors are one way of delivering this, with local lights augmenting dimmer overhead lights as people or vehicles enter an aisle or bay. However, it’s also possible to get even smarter with the use of an integrated warehouse management system (WMS). Lighting can be controlled through this system as people pass in and out, dynamically lighting the warehouse as they move around through the use of wireless sensors. When everybody has left, the system can immediately shut off the lights, safe in the knowledge that the warehouse is empty.

Better lighting

Controlling your lights is one thing, but how efficient are the lights themselves? Many warehouses still use old-fashioned sodium or metal halide lights, while others have since switched to fluorescent options. The older lights are a case for an immediate upgrade, as they are not just inefficient, but also give off an extremely warm light that doesn’t illuminate spaces properly. But even with fluorescent lights, there’s a good case to upgrade to LEDs.

While fluorescent lighting can save as much as 80% of the energy cost of older lighting, LED lights are as much as 50 times more efficient. Unlike fluorescent lights, they also produce little to no heat, and are fully and easily recyclable. The former point is particularly relevant in a refrigerated space, where LED lights can save you more money on cooling costs, and save as much as 60% of your CO2 emissions.

Walls and doors

Part of the difficulty in heating or cooling warehouses is that they are often cavernous spaces with numerous access points. Temperature is extremely important for maintaining goods in the right condition, and yet the size of the space means you have to heat or refrigerate them for hours on end, and often while nobody is there. This often has to be done regardless of how much stock you have at any given time, and where that stock is being held.

Properly insulated doors will help to maintain a steady internal temperature, particularly if an automated system ensures that the doors stay shut when they’re not in use (something that’s also helpful for fire protection). But one step that fewer warehouses have taken is to install partition walls. By subdividing your space, you can only heat or cool the areas you need at any given time – potentially leading to massive energy savings.

Landscaping

When you’re trying to improve the energy efficiency of your warehouse, it might seem counterintuitive to make changes to the area surrounding it. Yet you may be surprised to learn that the scenery around your warehouse can have a significant effect on how much energy is required to heat or cool it. As it turns out, a bit of landscaping can lead to a much more balanced climate around your warehouse, helping to maintain the right temperatures inside it.

Paving and similar surfaces around your warehouse can soak up heat from direct sunlight, and continue to radiate this out well into the evening and nighttime. That in turn can project additional heat onto your warehouse, requiring you to spend more time and energy cooling it down. By using grass and trees around the edge of your warehouse instead of stone slabs, you can ensure a cooler climate, and reduce the strain on your air conditioning.

Battery powered vehicles

Despite the apparently imminent revolution in robotics, many warehouses still rely on fuel-powered vehicles. While these forklifts are familiar and reliable, they pose both an environmental issue and a fuel-efficiency issue which can easily be rectified. Switching to battery-power solves a number of problems, and prepares your warehouse space for a future of autonomous vehicles.

Not only are battery-powered vehicles cheaper and more energy efficient, but they’re also emission-free. This massively reduces the need to ventilate your warehouse space for these emissions, which is often conducted by ventilation systems or simply keeping doors and windows open. In the former case, this can save you money on repairs; in the latter case, it saves you money on air conditioning.

Mezzanine floors

Reducing your carbon footprint isn’t just about longer-life bulbs; it can also mean consolidating your space and reducing your physical footprint. By building upwards instead of outwards, you can reduce the amount of empty space you need to heat or cool, and keep more of your goods closer together – delivering logistical benefits as well as energy efficiency.

By building a mezzanine floor in the headspace above your existing pallet racking, you can as much as double the available floor space in your warehouse. These mezzanines are extremely durable, and can be used for almost any application, from hosting heavy plant and machinery to office spaces, or simply more racking. By using your existing space more effectively, you can hold off on expansion to new properties – saving money on real estate as well as energy costs.

James Beale is the Operations Manager at Invicta Pallet Racking. For over 35 years Invicta has been at the forefront of the archive storage industry throughout the UK and Europe, designing and installing some of the largest warehouse racking systems currently found on the market.